Ngaio

Driven by Your Needs

Browse by Application

Use a team who understands the products they supply. As a customer you can have confidence that Ngaio only supplies quality products from reputable, global leading manufacturers, and has a local technical team to support them.

Ngaio Diagnostics is a privately owned supply company based in Nelson, New Zealand. Established in 1991, we specialise in the distribution and support of quality products to laboratories and commerical users throughout New Zealand, Australia and the Pacific Islands.

Ngaio Resource Exchange

Support Services:

We offer expert support services for studies, trials, and research projects. Our team can support with study design, product selection, and regulatory considerations to ensure seamless project execution. Working closely with professionals, researchers, & institutions, we provide valuable insights to ensure maximum efficiencies are achieved.

Learning & Education:

Our resources cover everything from detailed product features to best practices. In addition to written materials, we offer webinars, organise special symposiums, and host interactive sessions designed at deepening customer knowledge on the latest technologies, industry advancements, and effective application strategies.

Personalisation:

We understand that every healthcare, scientific and commercial setting has its own unique requirements. Whether you need specific sizes, features, or functionalities for your equipment, our team collaborates with you to develop the ideal solution for your practice, research, or clinical environment.

Ngaio : Driven by your needs

Latest News

Ensuring Food Safety with Zeulab’s Antibiotic Residue Testing Solutions

In a world where food safety is paramount, ensuring the absence of antibiotic residues in animal-derived products is not just…

Ngaio Appointed Exclusive NZ Partner for ALIFAX S.r.l Solutions

Ngaio Diagnostics Appointed Exclusive New Zealand Distributor for ALIFAX S.r.l. Microbiology Solutions Ngaio Diagnostics is proud to announce the exclusive…

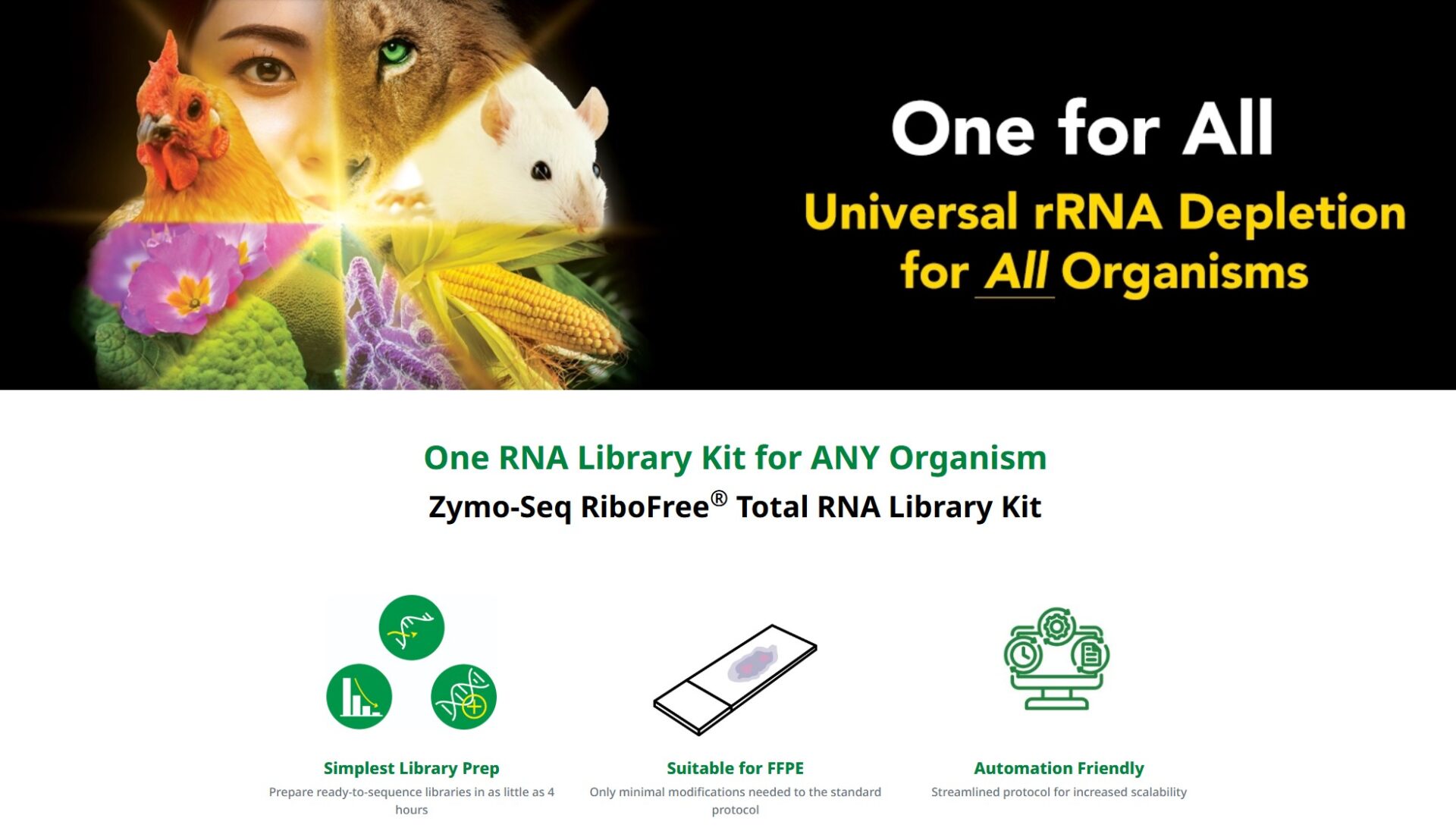

RNA-Seq: Exploring Beyond the Commonly Studied Model Organisms

The RNA sequencing revolution empowers all corners of biology: A Nature publish article by Zymo Research. Universal rRNA depletion can…